Key Benefits of Professional Roof Replacement Services

Outline of this guide:

– Why and when replacement makes sense, with signs to watch for and risks of delay

– Roofing materials compared by lifespan, weight, sustainability, and climate fit

– What professional installers actually do, from inspection to final clean‑up

– Cost drivers, value, and energy performance considerations

– How to select a reliable contractor and care for your new system long‑term

Why Roof Replacement Services Matter: Safety, Performance, and Timing

Roof replacement is not simply an aesthetic upgrade; it is a structural and financial decision with multi‑year consequences. A roof is a home’s primary weather shield, and once it begins to fail, water can migrate into decking, insulation, and wall cavities, leading to mold, diminished indoor air quality, and expensive repairs. Professional services bring standardized safety practices, code compliance, and access to materials and techniques that address both immediate protection and long‑term resilience. When timed well, replacement reduces emergency fixes and unplanned downtime while lifting curb appeal and resale potential.

Recognizing the right moment to replace rather than patch is central. Common indicators include:

– Granule loss that exposes shingle mat or smooth shiny spots on older membranes

– Widespread curling, cracking, or missing pieces after seasonal storms

– Soft or bouncy decking underfoot, suggesting moisture intrusion

– Stains along ceilings or in attic bays, especially near penetrations and valleys

– Rusted or failing flashing at chimneys, skylights, or wall intersections

Compared with recurring repairs, full replacement offers a chance to solve root causes. Installers can correct ventilation imbalances that trap heat and moisture, update underlayment to modern water‑resistant products, and replace outdated flashing assemblies that were never properly integrated. They also evaluate slope, drainage, and edge protection to reduce ice dams and wind uplift. For many homes, addressing these fundamentals at once can lengthen service life by years and stabilize utility costs through improved attic temperatures.

Risk management is another benefit. Professional crews carry insurance, follow fall‑protection standards, and pull permits where required. Documentation matters for warranties and for future buyers: an itemized scope, materials list, and inspection photos build confidence and may smooth a property transaction. While every home is unique, the logic is consistent: if you see pervasive wear, leaks in multiple locations, or repairs stacking up each season, a planned replacement with a clear scope is often the more economical and safer route over the next couple of decades.

Materials Compared: Lifespan, Climate Fit, Sustainability, and Aesthetics

Choosing material is the heart of a roof replacement strategy. Each option balances cost, longevity, weight, and appearance, and the right choice depends on local climate, structural capacity, and your maintenance preferences. Common systems and typical ranges include:

– Asphalt shingles: roughly 15–30 years, broad style range, relatively light

– Metal panels or shingles: roughly 40–70 years, excellent wind and fire resistance

– Clay or concrete tile: often 50+ years, heavy, distinctive texture and thermal mass

– Natural slate: often 75–100+ years, very heavy, classic, and highly durable

– Engineered composites: roughly 30–50 years, lighter than stone, consistent profiles

Climate is the deciding lens. In hot, sunny regions, reflective “cool” surfaces can reduce heat gain and may lower cooling loads; look for products with high solar reflectance and thermal emittance ratings, and consult local energy codes. In freeze‑thaw zones, impact‑rated materials and robust underlayment with ice and water barriers near eaves and valleys help resist ice dams. Coastal sites demand corrosion‑resistant fasteners and components designed for high wind uplift and salt exposure. In wildfire‑prone areas, assemblies with a Class A fire rating and ember‑resistant vents are prudent choices.

Weight and structure cannot be overlooked. Tile and slate deliver remarkable longevity but can weigh several times more than asphalt or metal. A qualified professional will verify rafter sizing, spans, and sheathing condition before recommending heavy systems. If structure is marginal, engineered composites or metal can deliver longer life without extensive reinforcement. Sustainability considerations include recycled content (common in certain metals), recyclability at end of life, locally sourced stone or clay, and cool‑roof performance that can mitigate urban heat.

Aesthetics remain important because a roof can cover 40% or more of a home’s visual elevation. Consider color stability, textured vs. smooth profiles, and how ridge, hip, and edge details shape the overall look. Request sample boards and view them in daylight at different hours. Ask installers to explain fastener exposure, concealed clips, and flashing trim so you understand how seams will appear from the street. Finally, confirm accessory compatibility—ridge vents, snow guards, and skylight kits—to ensure the finished assembly looks cohesive and performs well through seasonal extremes.

What Professionals Do: From Inspection to Final Clean‑Up

A professional roof replacement is an orchestrated sequence designed to reveal hidden issues and build a weather‑tight assembly. It begins with a thorough inspection: measuring planes and pitches, checking attic ventilation and insulation, probing decking for softness, and scanning for moisture stains around penetrations. A clear proposal follows that lists tear‑off scope, decking repairs, underlayment type, flashing metals, ventilation strategy, fasteners, and disposal plans. Permitting is handled where required, and start dates are coordinated with weather windows.

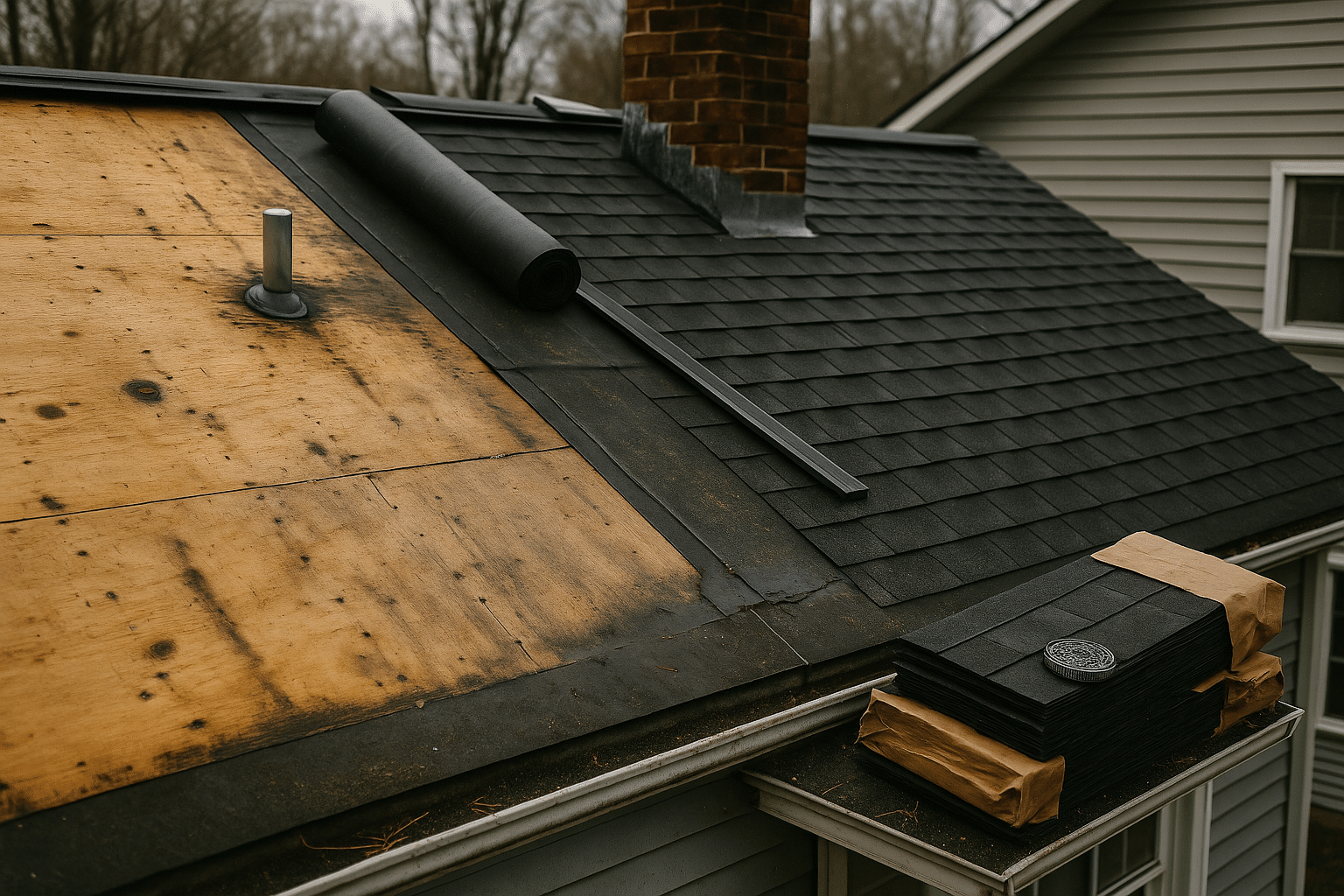

On installation day, safety setup comes first: fall‑protection lines, ladder stabilization, and protection for landscaping and siding. Tear‑off exposes the substrate so crews can replace rotten decking and correct irregularities that would telegraph through the new surface. Underlayment choices matter: synthetic felts resist wrinkling, and self‑adhered ice and water barriers guard eaves, valleys, and low‑slope transitions. Flashing is custom‑fit at walls, chimneys, and skylights using step, counter, and saddle pieces, with attention to shingle or panel coursing so water is always directed onto the surface, never behind it.

Ventilation is tuned to code and local conditions. Many codes reference a 1:150 net free ventilation area to attic floor area (or 1:300 when balanced and with specific vapor control), split between intake at eaves and exhaust at ridge or gables. Proper airflow reduces heat buildup that can age materials prematurely and minimizes condensation that leads to mold. Fastening patterns are set to manufacturer specifications and local wind zones, with nails or screws driven flush—not over‑ or under‑driven—to preserve pull‑out resistance and weather seal integrity.

Quality control includes straight, even coursing, sealed flashings, aligned ridges, and clean terminations at vents and edges. Debris is magnet‑swept from lawns and driveways, gutters are cleared, and leftover materials are documented for warranty registration. You should receive a close‑out package with:

– Photos of hidden areas like valleys and flashing before covering

– An itemized invoice and signed permit card, if applicable

– Warranty terms for both materials and workmanship

– Maintenance guidance for seasonal inspections and minor upkeep

This end‑to‑end process ensures the new roof is not just new, but properly integrated with the home’s envelope, ready for wind, rain, snow, and sun.

Cost, Value, and Energy Performance: What Influences the Numbers

Roof replacement costs vary widely because every home presents different challenges. Key drivers include:

– Material selection and accessory packages (vents, ice barriers, skylight upgrades)

– Roof size, pitch, story count, and the complexity of hips, valleys, and penetrations

– Decking condition, tear‑off layers, and disposal requirements

– Local labor rates, access constraints, and regional code upgrades

– Weather windows and project timing relative to demand

For context, many homeowners in the United States see totals that translate to roughly the mid‑single to low‑double digits per square foot for common systems, while premium tile or slate assemblies can be significantly higher due to materials, underlayment, and structural allowances. While sticker price matters, long‑term value also includes reduced repair frequency, potential insurance benefits from impact or fire ratings, and improved resale appeal. Industry cost‑versus‑value studies have often reported that a well‑executed replacement can recoup a meaningful portion of its cost at sale, especially when visible wear is eliminated and documentation is in order.

Energy performance is a practical angle. In warm climates, reflective surfaces and ventilated assemblies can lower attic temperatures, easing air‑conditioning loads during peak months. In cold climates, continuous air sealing at the ceiling, adequate insulation, and ice‑dam protection reduce heat loss and moisture problems that drive winter damage. Properly balanced intake and exhaust ventilation also helps maintain shingle or panel temperatures more evenly, lengthening service life. Homeowners who time replacement alongside attic air‑sealing and insulation upgrades often capture the most utility savings per dollar spent.

Budgeting and payment schedules should be transparent. Request a fixed‑scope proposal with allowances spelled out for decking replacement per sheet, and agree on a progress payment plan tied to milestones: delivery of materials, completion of tear‑off and substrate repairs, and final inspection. Ask about workmanship coverage in addition to material warranties. If you’re comparing proposals, normalize them by:

– Verifying underlayment types and coverage areas

– Confirming flashing metals and ventilation details

– Ensuring the same tear‑off and disposal scope

– Checking for code‑required items, such as ice barriers in cold regions

This apples‑to‑apples approach clarifies true value and helps you invest where performance gains are tangible.

Hiring Well and Caring for Your New Roof: A Practical Conclusion

Choosing the right professional is as important as choosing the right material. Start by verifying state or local licensing, active general liability and workers’ compensation insurance, and a permanent business address. Review recent, local project photos—ideally roofs similar to yours in slope and complexity—and ask for references you can call. A thorough proposal should outline materials, flashing details, ventilation plan, tear‑off and substrate repair allowances, estimated start/finish dates, and clean‑up procedures. Clarity now avoids surprises later.

Interview more than one company and ask consistent questions:

– How will you protect landscaping, siding, and interior spaces during work?

– What is the plan if decking damage is more extensive than expected?

– Which crew will be on site daily, and who is my point of contact?

– How do you handle weather delays and keep the home dry overnight?

– What are the workmanship warranty terms, and what maintenance keeps it valid?

Watch for red flags like vague scopes, unusually low prices with unclear materials, pressure to sign immediately, or requests for large deposits far in advance of material delivery. A professional will welcome questions, explain options without overselling, and provide documentation for permits and inspections. Once installed, care is straightforward: keep gutters clear, trim back branches, and schedule a visual check each spring and fall, plus after major storms. From the attic, look for daylight around penetrations, damp insulation, musty odors, or rusty nail tips—subtle clues that merit a quick call before issues spread.

Register warranties promptly, store your proposal and photos, and note the installation date for future planning. Consider a simple annual checklist:

– Clear debris from valleys and roof‑to‑wall transitions

– Verify ridge and intake vents remain unobstructed

– Inspect sealant at exposed fasteners and accessories

– Check that splash lines below downspouts aren’t undermining foundations

Handled this way, a roof replacement becomes a durable upgrade that protects your investment, steadies energy use, and frames your home with a clean, confident profile. With a thoughtful material choice, a documented process, and a reliable professional, you set the stage for decades of dependable shelter—exactly what a roof is meant to provide.